Brief Concept Description

BASSE is an active façade composed of an unglazed collector and a steel sandwich panel which can harvest low temperature heat from solar radiation. The design of this innovative solar envelope system and its use in combination with a heat pump were studied as part of a research project concluded in 2016 (BASSE-Building Active Steel Skin). A key factor to potentially reach high production is its industrial design that enables a reduction of costs, a higher level of feasibility in the performance, and the support of an already mature industry such as the one of steel panel manufacturers with a robust value chain.

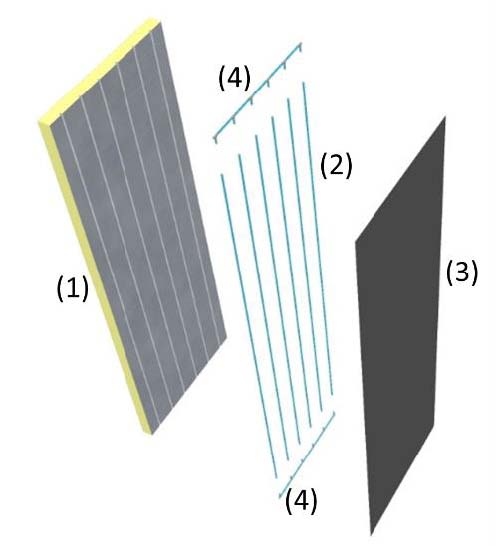

As shown in Figure 43, the active façade is composed of five main elements. A sandwich panel (1) made of a polyurethane insulation core is enclosed in two slotted steel skins. Plastic pipes (2) are installed into the slots of the external skin and covered by a finishing steel layer (3) that acts as a solar absorber. Each panel integrates 6 parallel pipes interconnected by completely modular headers or manifolds (4). Concerning the size of the collector, a standard panel is about 3 m long, 1 m wide and 0.8 m thick.

Figure 43. Main components of the BASSE – Building Active Steel Skin.

This active skin element is developed for the installation in the opaque areas of the envelope and the dimensions of the single panel (especially the length) can in line of principle reach even 15 meters limited by transportation possibilities, although the collector efficiency significantly decreases for such large areas. The solution exploits the high conductivity of steel in a low temperature collector (<50ºC), which alone is not enough to cover the energy needs of a building but when coupled with a heating device (like a heat pump or a boiler) significantly increases the efficiency of both collector and heating system.

In the final demonstration stage, a complete system was installed in a real building and the performance of 18 m2 area of active façade were demonstrated, also in combination with a heat pump. The definition of the complete system was a joint development among TECNALIA, TATA STEEL, DOW CHEMICAL, ETL EUROPEAN THERMODYNAMICS and NIBE.

Architectural and Technological Integration into the Envelope

The concept is based on a modular and metallic design resulting into a system that externally cannot be differentiated from a standard sandwich panel. Such appearance is more popular in industrial and tertiary buildings but is less usual in offices and especially in the residential sector. However, the recent interest in the field of façades for advanced coatings and technologies represent a clear opportunity for this metallic skin to provide modern and technically sophisticated solutions.

Figure 44. Picture of 18 m2 assembly of BASSE composed of 6 panels installed in the Kubik test facility.

Integration into the Building: System and Comfort

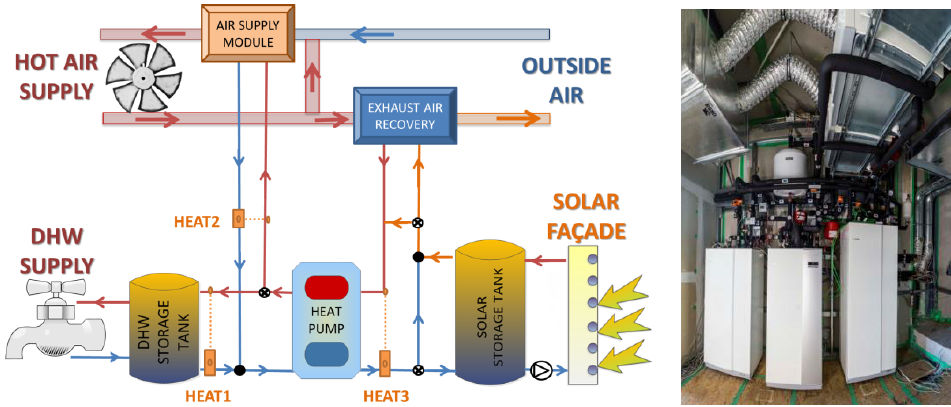

The complete system presented in Figure 45 (left) is designed to provide warm air and DHW by means of a heat pump connected to the low temperature solar collector and a heat recovery system on the source side. The system is completed by two water thermal storages, one in the solar circuit and one in the DHW circuit. The liquid circulating through the heat pump and solar circuit is a water-alcohol mixture to avoid freezing in cold season and reduce the electricity consumption during operation. The main source of electricity consumption is the heat pump, but also the circulating pumps on solar circuit and on the connections with the ventilation system are cause of consumption.

Figure 45. Complete system schematics with heat pump and solar façade as main elements (left) and utility room with installed equipment for the complete HVAC system (right).

Further Reading

Elguezabal, P., Lopez, A., Blanco, J. M., & Chica, J. A. (2020). CFD model-based analysis and experimental assessment of key design parameters for an integrated unglazed metallic thermal collector façade. Renewable Energy, 146, 1766–1780. https://doi.org/10.1016/j.renene.2019.07.151

S. Boudjabeur, et al., Building active steel skin. (BASSE). Grant agreement nº: RFSR-CT-2013 - 00026. Final report, ISBN 978-92-79-94133-7. ISSN 1831- 9424

Elguezabal, P., Garay, R., Martin, K., (2017). Experimentation under real performing conditions of a highly integrable unglazed solar collector into a building façade. Energy Procedia. Vol. 122 (2017), 775-780. DOI. https://doi.org/10.1016/j.egypro.2017.07.395

Acknowledgment

The BASSE project received funding from the European Union, RFCS Program, Research Fund for Coal and Steel project Building Active Steel Skin (BASSE, Grant Agreement no RFSR-CT-2013-00026).