Brief Concept Description

The SUNERG X - Color Monocrystalline module, produced by the Italian company Sunerg, is a custom-made BIPV panel suited for both roof and facades applications that is available in a range of colours. Such solution targets a niche market where blue polycrystalline or black monocrystalline modules cannot satisfy aesthetics requirements due to colour and offers instead a range of options (mahogany brown, reddish brown, bottle green and black-grey) that can better match the architectural vision and the design of the building. The PV modules are produced in a standard size (275 Wp) with an aluminium frame and back sheet in the chosen colour.

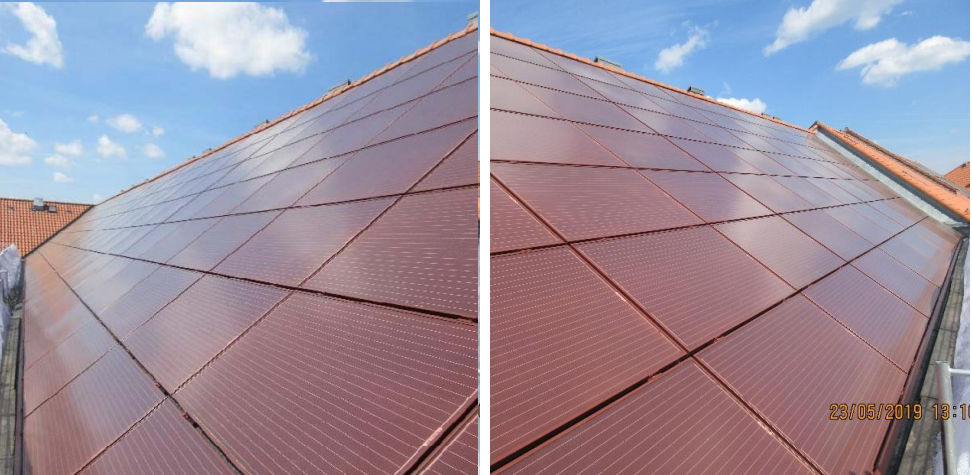

Figure 20. SUNERG X – Color monocrystalline modules in roof application, colour of the module: chestnut brown (RAL 8015) (Source: Solar Lightning Consultants ApS - Architect Martin Dietz (C)).

Architectural and Technological Integration into the Envelope

SUNERG X – Color is available in a range of colours to match the design of the envelope where they are integrated. It is possible to have frames, clamps, cable box etc. coloured as the BIPV panels to achieve better aesthetics and a seamless integration. To add more flexibility, special dummies with mono cells and the same coloured glass, frame and back sheet can be attached to the envelope and adjusted to the size and dimension of the roof / BIPV design. Such dummies are not connected to the grid but have the same appearance of the other BIPV modules. Durability and maintenance cost are similar to that of a normal passive glass facade.

For roof applications, two kinds of envelope design approach, can be chosen: (A) full BIPV integration or (B) integration of the BIPV modules, where PV modules are installed in an “floating architectonic structure” on top of the roof (waterproof asphalt roofing underneath).

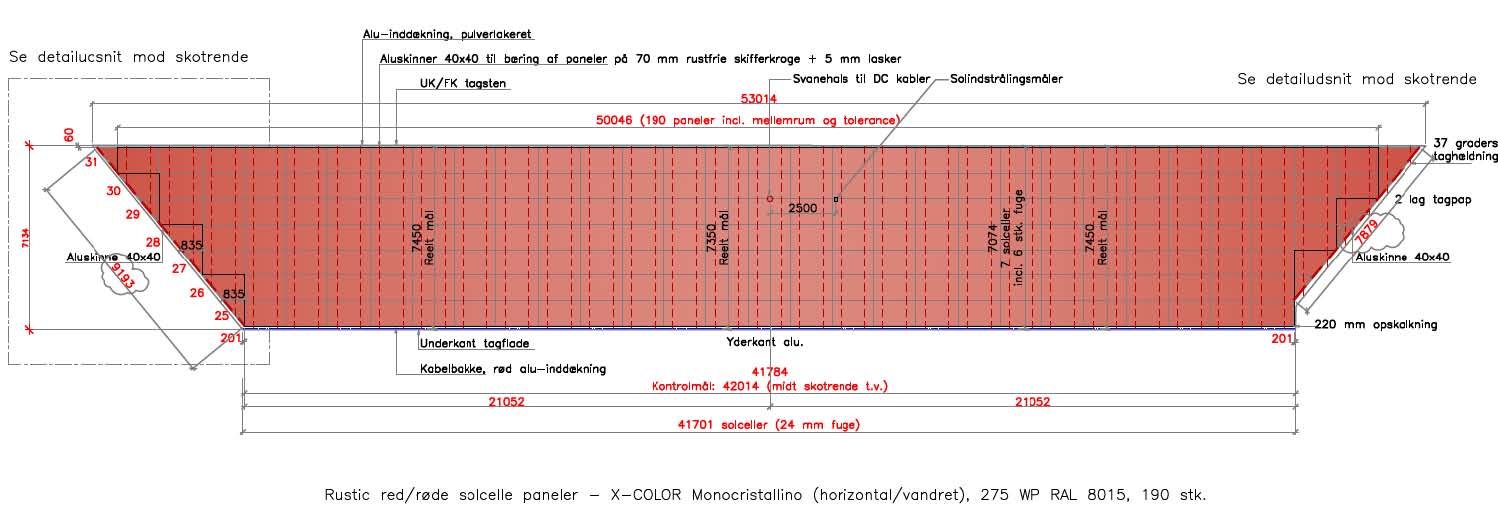

Concerning the technological integration into the envelope, the modules can be installed in a horizontal or vertical configuration according to the architectonic design of the roof or façade. In the project “AB Landsdommergaarden” in Copenhagen (Figure 21), the installation process of the BIPV system into the roof (envelope design approach B) can be detailed as follow: In a first step, the existing cover and wooden rails were removed and a waterproof of 2layers asphalt roofing was laid on top of the ceiling. Then, a metal hook was fixed to support the aluminium rails and the rail structure was mounted. Wiring, cable trays and cable boxes were installed. Afterwards, the PV modules were fixed to the aluminium rails with clamps. A number of solar inverters and sensors (including a sun irradiation meter) were put in place to complete the DC installation. Finally, the AC cables were laid vertically along a back staircase and connected to a secondary electricity power meter to measure PV production and connected to a main electricity cabinet in the basement.

Figure 21. The 52,25 kWp BIPV installation on the roof of “AB Landsdommergaarden” in Copenhagen (Denmark) covers 22 % of the residential electricity consumption. Electricity output: 47.340 kWh during the first year. Estimated CO2 emissions saved 29.154 kg per year. (Source: Solar Lighting Consultants ApS).

Figure 22. Schematic drawings of the BIPV installation on the roof of “AB Landsdommergaarden” in Copenhagen, Denmark. (Source: Solar Lighting Consultants ApS).

Figure 23. Views of the BIPV installation on the roof of “AB Landsdommergaarden” in Copenhagen, Denmark. (Source: Solar Lightning Consultants ApS - Architect Martin Dietz (C)).

Disclaimer

The information and views set out in this chapter of the report are those of the author and do not necessarily reflect the opinion of SUNERG Solar Srl.