Brief Concept Description

GAP Solutions is dedicated to the development and implementation of innovative, sustainable and value-enhancing passive solar system solutions for residential constructions, such as the GAP:water façade shown in Figure 1 conceived for solar domestic hot water generation.

Hot water preparation constitutes a relevant share of the energy demand in modern residential buildings, since the use of improved envelope systems and ventilation concepts drastically reduces the space heating energy demand: in highly energy efficient houses, domestic hot water generation represents at least 60% of the total heat requirement.

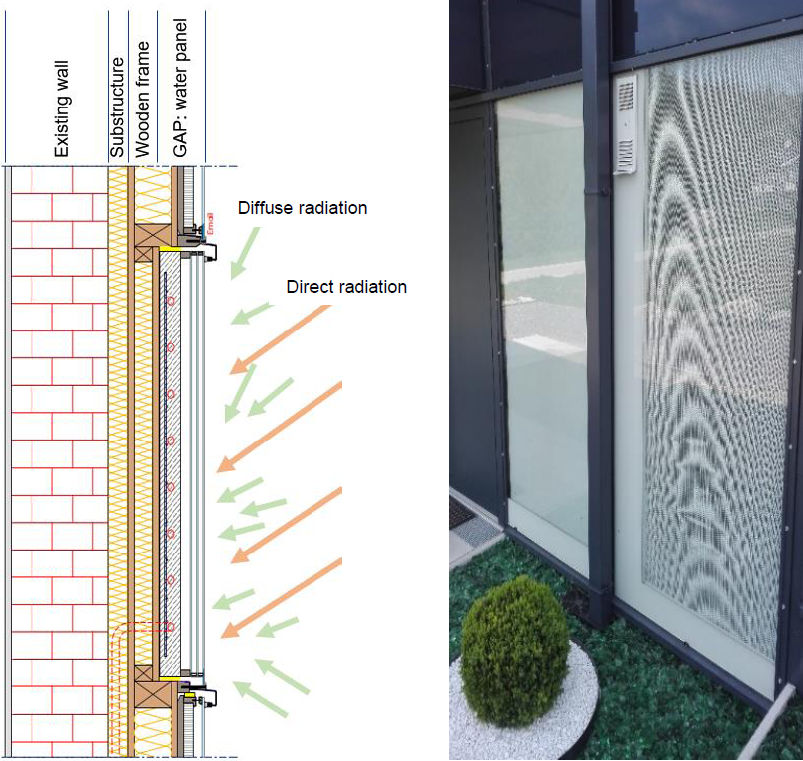

GAP:water is a new and patented low-tech solution that integrates a decentralised solar system for water heating into a prefabricated solution. The core element is a concrete storage solar absorber with a cast-in water heat exchanger which is installed into the building’s envelope in the immediate vicinity of the point of consumption of hot water. The concrete absorber is covered by a very good insulating glass and enables to convert the impinging solar radiation into heat which is stored into its concrete structure. The embedded heat exchanger enables to access the stored heat to pre-heat the fresh water required for domestic use. At the outlet of the collector, a heat generator (e.g. a boiler) is used to heat the water flow to the desired temperature.

The energy savings are large, since the temperature of the solar pre-heating is in many cases already sufficient for hot water preparation. Unlike conventional solar systems, the use of large water distribution networks or water tanks including pumps and electronics (active control) is not required.

Figure 24. Schematic drawing (left) and view (right) of the GAP:water façade.

Architectural and Technological Integration into the Envelope

The GAP:water system is integrated into prefabricated structures as the GAP:skin façade (see dedicated chapter in the report). As seen, the main component of the GAP:water panel is a concrete storage/solar absorber that is enclosed in an insulating cover glass and integrates a heat exchanger. Such panel is installed in a wooden frame that is fixed to the levelling layer, which includes a wooden substructure and insulation material. Also at times when there is no hot water demand, GAP:water is a good thermal insulation layer.

The system does not require pumps, an active control or antifreeze protections. The combination of the storage mass of the concrete collector and the insulating glass properties (U-values <0.6 W/m².K with g-values >55%) ensures high frost resistance. There is also no overheating of the concrete collector (hot water) throughout the year. The use of the collector is not limited to South-exposures.

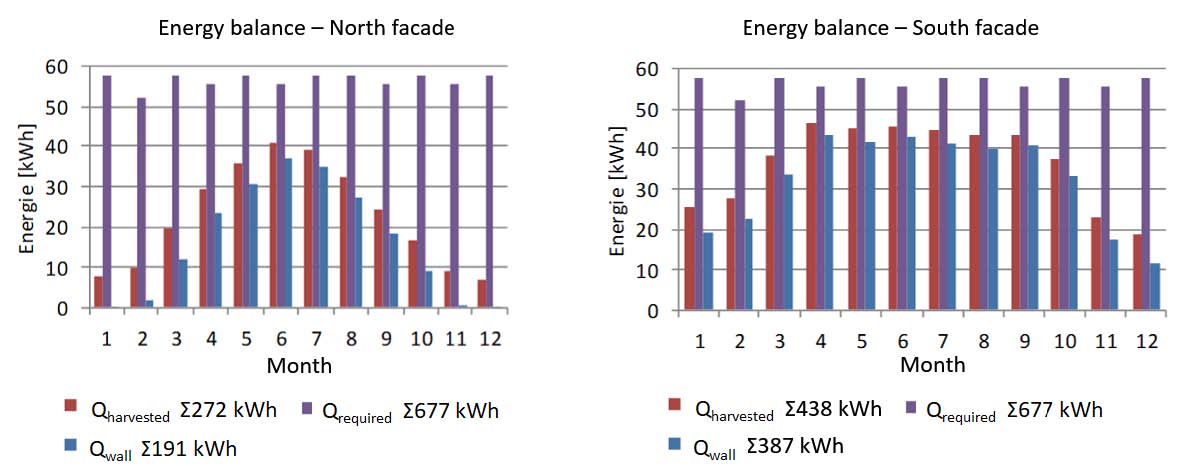

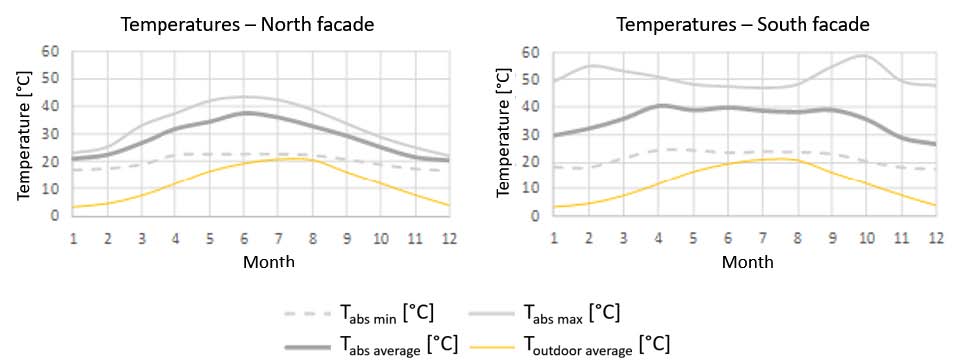

To show the potential of this solution, Figure 25 presents the monthly energy balance for a GAP:water installation on a North and a South facade of a 2-people dwelling located in Frankfurt. Figure 26 shows a set of monthly temperatures simulated in the middle of the concrete core of the collector, i.e. temperature of the water heat exchanger. As it can be seen, the façade shows optimal performances for the South façade, but its use is also possible for North facades. It can also be observed how the minimum temperatures in the core of the concrete collector do never reach values close to the freezing point, even for low outdoor temperatures.

Figure 25. Simulated monthly energy balance for a GAP:water installation in Frankfurt (Germany) and a 2-people dwelling. Qrequired (purple) is the hot water preparation energy load, Qharvested (red) is the amount of energy harvested by GAP:water and Qwall (blue) is the energy delivered to the room via the rear wall.

Figure 26. Temperature trends for a GAP:water installation in Frankfurt, Germany. Tabs min (grey dashed), Tabs max (light grey) and Tabs average are respectively the minimum, the maximum and the average temperatures in the middle of the concrete core (water pipe). Toutdoor average (yellow) is the average outdoor air temperature.

Integration into the Building: System and Comfort

The pipe connections to the concrete collector reach the interior of the building through core drill holes in the existing wall. As this system is decentralized and close to the point of consumption, long supply lines and thus high distribution losses are prevented. As discussed above, GAP:water pre-heats fresh water but a generator is required to heat the water to the desired temperature. If needed, the system can also be integrated into the existing building services. This system was already used in 2010 for the renovation of the residential complex in Leoben/Austria in 256 residential units with very good results (Figure 27). The system enables the production of domestic hot water over the year with energy savings between 35% (North side) and 75% (South side) with a 3 to 4 m² concrete storage absorber for each dwelling.

Figure 27. GAP:water panels (left) and GAP:water installation in Leoben, Austria (right).

Further Reading

The building stock is a major cause of CO2 emissions. Europe has already been built - that is why the conversion of Europe to CO2-free building management must start there. In renovated buildings, the proportion of hot water increases sharply in relation to the heating energy requirement. The technological implementation has been "grasped" for many years in best practice examples.

More information on Photovoltaic Water Solution is available here: Passive House Renovation Graz, facadeintegrated DC-based hot water preheating, final report: Reports from Energy and Environmental Research 00/2010

https://nachhaltigwirtschaften.at/de/hdz/projekte/photovoltaik-water-solution.php

Company Website: www.gap-solutions.at